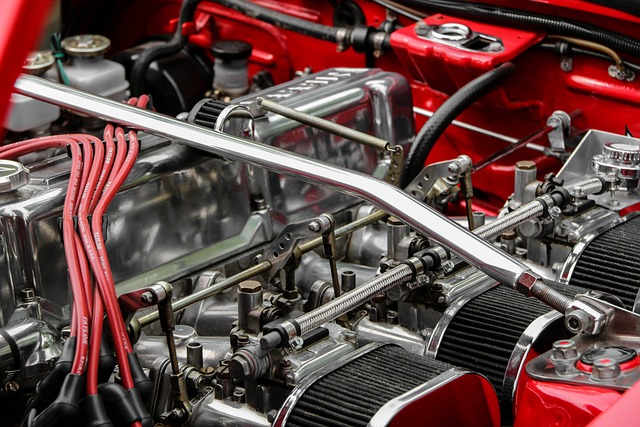

Spot welding equipment is vital for auto body professionals, enabling precise control over welds to preserve vehicle specifications and structural integrity. Its advanced features minimize damage, ensuring efficient repairs while retaining original strength, rigidity, and aesthetic appeal, especially crucial for luxury vehicles. This precision allows for accurate restoration of vehicles to pre-incident conditions, extending their lifespan without compromising performance or aesthetics.

Spot welding equipment is an essential tool for preserving original vehicle specifications. In the automotive industry, maintaining the integrity and accuracy of vehicle components is paramount. This article explores how advanced spot welding techniques, facilitated by specialized equipment, ensure that every welded joint meets exact manufacturer standards. By delving into the key aspects of spot welding equipment, we uncover how it plays a pivotal role in preserving the original design, functionality, and safety of vehicles, making it an indispensable asset for modern auto repair and manufacturing.

- Spot Welding Equipment: Essential Tool for Preservation

- Maintaining Original Vehicle Specifications Accurately

- Preserving Integrity Through Precision Welding Techniques

Spot Welding Equipment: Essential Tool for Preservation

Spot welding equipment is an essential tool for preserving original vehicle specifications, especially in the hands of skilled auto body shop professionals. This specialized machinery facilitates precise and efficient welds, ensuring that components align perfectly with the manufacturer’s designs. By employing spot welding techniques, auto maintenance experts can perform car body repairs while maintaining the structural integrity and aesthetic appeal of the vehicle.

Compared to other welding methods, spot welding offers greater control over heat input, minimizing damage to surrounding materials. This meticulous approach is particularly crucial when dealing with intricate automotive parts, ensuring that every weld point adheres strictly to the original specifications. As a result, vehicles undergo minimal metamorphosis during repair processes, preserving their indelible identity and value.

Maintaining Original Vehicle Specifications Accurately

Maintaining original vehicle specifications accurately is paramount when it comes to spot welding equipment. This advanced technology is designed to precisely join metal components, ensuring that the final product matches the manufacturer’s intended design. By controlling factors like heat input, energy delivery, and weld time, spot welding equipment allows for repeatable and consistent results, preserving the integrity of the vehicle’s original structure. This is particularly crucial in scenarios such as fender repair or collision repair, where maintaining the car’s original specifications can impact safety and handling.

In the event of a minor incident, like a fender bender, having accurate spot welding equipment on hand enables efficient repairs that minimize structural alterations. The ability to precisely recreate the manufacturer’s welds ensures that the vehicle retains its original strength, rigidity, and overall performance characteristics. This meticulous approach not only preserves the car’s value but also guarantees a seamless integration of new components with existing structures, effectively extending the life of the vehicle without compromising its original specifications.

Preserving Integrity Through Precision Welding Techniques

Spot welding equipment plays a pivotal role in preserving the integrity and original specifications of vehicles, particularly during collision damage repair or paintless dent repair processes. The precision of spot welding ensures that components are joined accurately, maintaining the vehicle’s structural stability and aesthetic appeal. This is especially crucial for luxury vehicle repairs where meticulous craftsmanship is expected.

Through advanced techniques, spot welding equipment minimizes distortion and creates strong, permanent bonds. It allows for precise control over heat input, ensuring welds are consistent and conform to original design standards. This level of precision is invaluable in restoring vehicles to their pre-incident condition, be it a minor dent or significant collision damage.

Spot welding equipment plays a pivotal role in preserving original vehicle specifications by enabling precise and controlled welds. This technology ensures that structural integrity is maintained, adhering to manufacturer standards. By utilizing advanced spot welding techniques, auto restoration experts can accurately replicate original designs, guaranteeing both performance and aesthetic excellence. Invest in high-quality spot welding equipment to safeguard the historical accuracy of vintage vehicles while meeting modern safety standards.