Spot welding equipment is vital in Mercedes-Benz collision repair, ensuring precise reconstruction and maintaining original quality, lines, and performance. This advanced technology creates structural soundness and precision, aligning with OEM standards, ultimately preserving restored vehicle value and aesthetics. In car paint repair and vehicle restoration, spot welding guarantees meticulous panel alignment and structural integrity, enhancing customer satisfaction.

Spot welding equipment is a crucial tool for preserving original vehicle specifications, ensuring structural integrity and accuracy. This advanced technology enables precise welds, critical for automotive restoration projects. By maintaining exact dimensions and shapes, spot welding preserves the vehicle’s initial design intent, enhancing its overall value. The article delves into these aspects, exploring how spot welding equipment plays a pivotal role in upholding vehicle standards during both new construction and restoration processes.

- Spot Welding Equipment: Key to Preserving Vehicle Integrity

- Maintaining Original Specifications through Precise Spot Welds

- The Role of Spot Welding in Automotive Restoration and Accuracy

Spot Welding Equipment: Key to Preserving Vehicle Integrity

Spot welding equipment plays a pivotal role in preserving the integrity and original specifications of vehicles, particularly during auto body repairs. This advanced technology is crucial for maintaining the precision and structural soundness of modern automotive designs, which often feature intricate metal formations. With its ability to join metal sheets with minimal distortion, spot welding ensures that the repaired area matches the vehicle’s original quality.

In the realm of Mercedes-Benz collision repair, where meticulous craftsmanship is paramount, spot welding equipment becomes an indispensable tool. It facilitates the accurate reconstruction of panels and components, ensuring the restored vehicle retains its sleek lines and superior performance. By employing this method, automotive repair specialists can deliver top-tier results that meet or exceed original equipment manufacturer (OEM) standards, making it a key component in preserving the vehicle’s overall value and aesthetics.

Maintaining Original Specifications through Precise Spot Welds

Maintaining Original Specifications through Precise Spot Welds

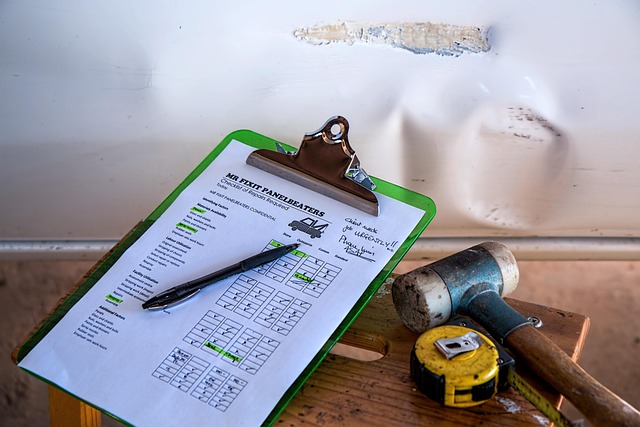

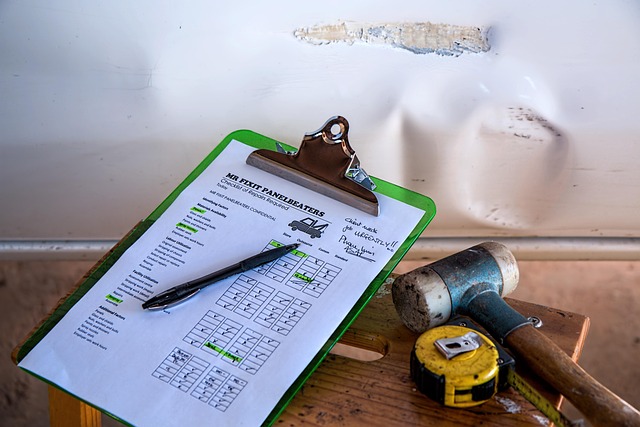

Spot welding equipment plays a pivotal role in ensuring that vehicle repairs adhere to the manufacturer’s original specifications. Unlike other joining methods, spot welding allows for precise, controlled heat application, making it ideal for auto body repair and bumper repair scenarios within collision centers. This precision is crucial because it preserves the structural integrity of the vehicle while restoring its aesthetic appeal.

By using advanced spot welding equipment, technicians can achieve strong, durable bonds that closely mimic the original manufacturing process. This is particularly important in complex sections like panels, fenders, and doors where maintaining the vehicle’s original specifications is not just about appearance but also about safety and performance. The result is a high-quality repair that looks as good as new, ensuring the vehicle retains its original design and structural attributes.

The Role of Spot Welding in Automotive Restoration and Accuracy

In the realm of automotive restoration, achieving precision and preserving original vehicle specifications are paramount. Spot welding equipment plays a pivotal role in this process by enabling meticulous and accurate joining of metal components. This technique is particularly crucial for car paint repair and vehicle restoration, ensuring that every detail, from panel alignment to structural integrity, meets the manufacturer’s standards.

When it comes to collision repair centers, spot welding equipment ensures that repairs are not just cosmetically appealing but also structurally sound. By accurately fusing metal panels back together, these specialized tools help restore vehicles to their pre-incident condition, maintaining their original specifications and aesthetic appeal. This level of precision is vital for customer satisfaction and ensuring the safety and reliability of restored vehicles.

Spot welding equipment plays a pivotal role in preserving original vehicle specifications during restoration projects. By enabling precise welds, this technology ensures that modern automotive restoration techniques maintain the accuracy and integrity of classic or vintage vehicles. With the right tools, restorers can meticulously replicate the manufacturer’s intended design, making each restored car a testament to historical automotive craftsmanship.