Spot welding equipment revolutionizes automotive repair by offering precision, efficiency, and strength for seamless panel replacements, minimizing labor costs, and ensuring top-tier collision repair quality. Its advanced technology produces clean, strong bonds, meeting original manufacturing standards, even in tight spaces, making it ideal for paintless dent repair and various repair tasks. Choosing the right spot welding equipment is crucial for auto body shops aiming to deliver high-quality, durable repairs.

In the automotive industry, efficient panel replacement is key to maintaining vehicle quality and integrity. Spot welding equipment stands out as a preferred choice due to its precision and efficiency. This article explores why spot welding is an optimal solution for panel replacement, highlighting its advantages over traditional methods. We’ll delve into how spot welding ensures both accuracy and speed, while also discussing the importance of selecting the right equipment for long-lasting, durable results in any manufacturing setting.

- Advantages of Spot Welding for Panel Replacement

- Efficiency and Precision in Action

- Choosing the Right Equipment for Durability

Advantages of Spot Welding for Panel Replacement

Spot welding equipment offers several advantages for panel replacement in vehicle body shops and hail damage repair scenarios. One of its key benefits is precision; this method allows for accurate, controlled welds, ensuring that new panels fit seamlessly into existing structures, even after a vehicle collision repair. This precision reduces the risk of misalignment or uneven gaps, which can be both unsightly and structurally compromising.

Furthermore, spot welding is a time-efficient process. Compared to other joining techniques, it minimizes setup times since specialized equipment can quickly create strong welds. This efficiency translates into reduced labor costs for body shop services, making it an attractive option for businesses looking to streamline their operations while maintaining high-quality results in vehicle collision repair.

Efficiency and Precision in Action

Spot welding equipment stands out for its efficiency and precision when it comes to panel replacement tasks, making it a preferred choice in automotive collision repair and bumper repair scenarios. This advanced technology enables accurate and consistent welds, which is crucial for ensuring structural integrity and aesthetic appeal in paintless dent repair processes.

The precision offered by spot welding equipment allows for precise control over heat input, resulting in clean, strong bonds that match the original manufacturing standards. This level of accuracy is particularly valuable in tight spaces where manual techniques might struggle, ensuring efficient workflow and top-quality repairs in both collision and bumper repair settings.

Choosing the Right Equipment for Durability

When it comes to panel replacement, especially in auto body shops, selecting the right spot welding equipment is paramount for achieving long-lasting results. This isn’t just about convenience; it’s a crucial step in ensuring the structural integrity and durability of the vehicle. High-quality spot welding equipment offers precise control over heat input, allowing technicians to weld metal panels with minimal distortion.

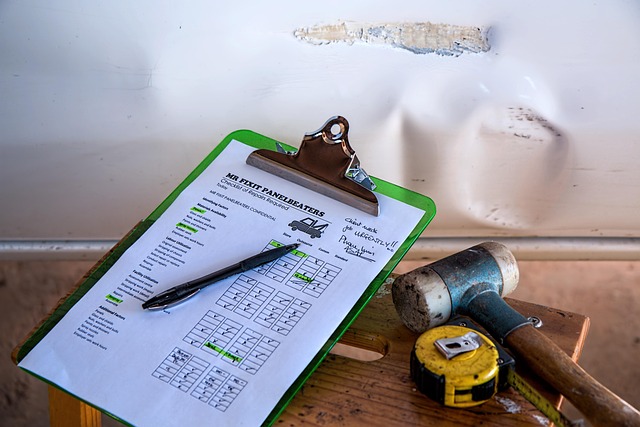

This meticulous process, as opposed to more haphazard methods like hammering or general adhesive bonding, results in stronger bonds that better withstand the stresses of everyday driving. For auto body shops tackling everything from minor car dent removal to significant car damage repair, investing in robust spot welding equipment pays dividends over time.

Spot welding equipment stands as a preferred choice for panel replacement due to its unmatched efficiency, precision, and durability. By leveraging advanced technology, this equipment ensures swift and accurate welds, streamlining the replacement process. When selecting spot welding machinery, prioritizing quality and adaptability ensures long-lasting results, making it an indispensable tool in various industries. Invest in the right gear, and you’ll unlock a seamless, efficient approach to panel repairs.