Spot welding equipment has revolutionized collision repair, offering faster and stronger bonds through precise metal melting. Specialized guns and power sources ensure high-quality, consistent welds on modern and classic cars, reducing repair times and turnaround for customers while maintaining structural integrity. This advanced technology streamlines processes, automates tasks, and enhances efficiency in body shops, making it ideal for intricate repairs like auto glass and classic car restoration.

Spot welding equipment has revolutionized collision repair, significantly shrinking turnaround times. This article delves into how advanced spot welding technology is transforming the automotive industry. We explore its role in revolutionizing collision repair processes, the time-saving techniques of efficient equipment, and the evolution from manual to automated systems. By understanding these aspects, you’ll grasp why spot welding equipment is an indispensable asset for modern auto body shops.

- Revolutionizing Collision Repair: Spot Welding's Role

- Time-Saving Techniques: Equipment Efficiency

- Streamlining Processes: From Manual to Automated Systems

Revolutionizing Collision Repair: Spot Welding's Role

Spot welding equipment has revolutionized collision repair processes, significantly reducing timelines and enhancing efficiency. This advanced technique, characterized by precise, localized melting of metal to join pieces together, offers several advantages over traditional bonding methods. By employing specialized spot welding guns and power sources, professional technicians can achieve strong, durable bonds in a fraction of the time it takes for manual or other automated processes.

In the realm of body shop services and collision repair shops, spot welding equipment plays a pivotal role in streamlining workflows. Its versatility allows for intricate repairs on both modern vehicles with advanced materials and classic car restoration projects demanding precise craftsmanship. This technology’s capability to create consistent, high-quality welds ensures structural integrity, contributing to safer and more reliable vehicle returns for customers.

Time-Saving Techniques: Equipment Efficiency

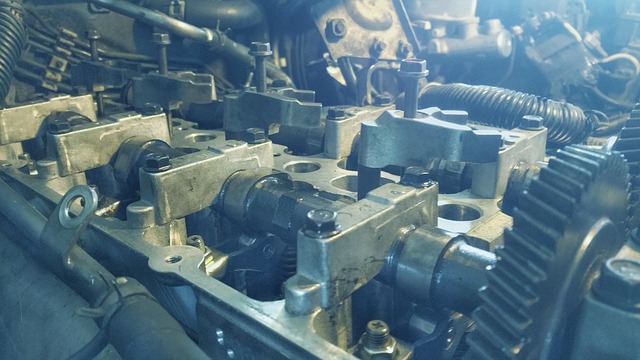

The efficiency of spot welding equipment is a game-changer when it comes to collision repair, offering significant time savings compared to traditional methods. By utilizing specialized tools designed for precision and speed, auto painting and car paint services professionals can streamline the vehicle dent repair process. These machines enable quick and reliable welds, reducing the time spent on each repair task.

The advanced technology incorporated into modern spot welding equipment ensures efficient energy transfer, allowing technicians to perform high-quality repairs faster. This efficiency translates to shorter turnaround times for collision centers, improving overall productivity. As a result, customers benefit from quicker vehicle restoration, ensuring their cars are back on the road in no time while maintaining top-notch aesthetics and structural integrity.

Streamlining Processes: From Manual to Automated Systems

In traditional collision repair processes, many steps were once performed manually, leading to longer timelines and potential inefficiencies. However, the introduction of spot welding equipment has revolutionized this landscape. This modern technology streamlines various stages of the repair process, from panel alignment to joining metal components. By automating these tasks, body shop services can significantly reduce turnaround times without compromising quality.

Spot welding equipment offers precise control over heat input, allowing for efficient and consistent welds. This precision is particularly beneficial in intricate auto glass repair and classic car restoration projects, where accuracy is paramount. The automated nature of spot welding equipment ensures that each repair follows a standardized, optimized procedure, eliminating the variability associated with manual labor.

Spot welding equipment has emerged as a game-changer in collision repair, revolutionizing processes and significantly reducing timeline. By employing efficient time-saving techniques and automating tasks previously done manually, modern spot welding systems streamline operations, enabling faster turnaround times and higher quality repairs. This advanced technology is a testament to how innovative tools can transform industries, ensuring folks in the automotive sector have robust, reliable options for enhancing their work.