Spot welding equipment is a vital tool for automotive and collision repair, enabling efficient joining of high-strength steel (HSS) components with precise energy delivery. It offers clean, strong bonds, expediting repairs while preserving structural integrity. HSS's superior strength demands specialized spot welding techniques to prevent damage, and advanced machines use algorithms to optimize welds, enhancing vehicle reliability and streamlining manufacturing.

Spot welding equipment plays a pivotal role in joining high-strength steels, enabling robust and precise connections. This article delves into the intricate world of spot welding, exploring its fundamental principles and its symbiotic relationship with advanced steel grades. We’ll examine how high-strength steels, known for their exceptional properties, present unique challenges that require tailored welding techniques. By optimizing these processes, we can unlock the full potential of modern steel, ensuring structural integrity in various industries.

- Understanding Spot Welding Equipment Basics

- High-Strength Steels: Properties and Challenges

- Optimizing Spot Welding for Enhanced Strength

Understanding Spot Welding Equipment Basics

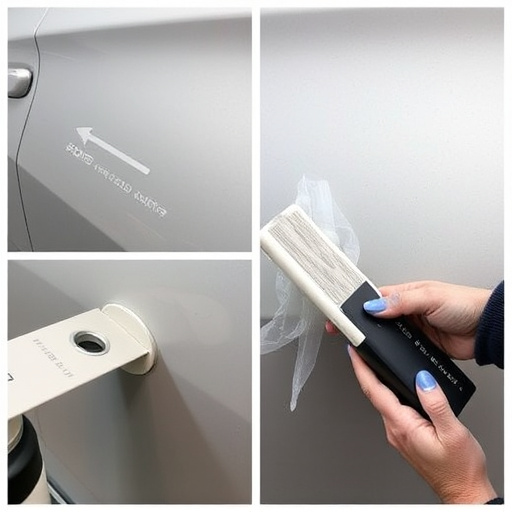

Spot welding equipment is a specialized tool used in the automotive industry and collision repair centers for joining metal components quickly and efficiently. This process involves applying precise electrical energy to create a weld between two pieces of high-strength steel, often found in modern vehicles. The equipment consists of various components, including power supplies, electrode holders, and control systems, all designed to deliver consistent and powerful welding current to ensure strong bonds.

In automotive repair services, spot welding is valuable for its ability to create clean, precise joins without the need for extensive preparation or material consumption. It’s a game-changer in collision repair centers, enabling faster restoration of damaged vehicles while maintaining structural integrity. The equipment’s versatility allows for various weld patterns and configurations, catering to different auto repair needs and ensuring high-quality results.

High-Strength Steels: Properties and Challenges

High-Strength steels (HSS) have revolutionized various industries, including automotive manufacturing and tire services. These advanced materials offer exceptional strength, durability, and resistance to corrosion, making them a preferred choice for modern car body repair and vehicle collision repair processes. However, working with HSS presents unique challenges for spot welding equipment.

Compared to traditional steels, HSS require specialized welding techniques and settings due to their high hardness and tensile strength. In the case of spot welding, which is commonly used in assembly lines for joining metal components, adjustments are necessary to ensure effective bonding without damage to the HSS surface or structural integrity. This often involves precise control over heat input, pulse duration, and current intensity to manage the melting and solidification process, leading to robust welds that can withstand rigorous testing in tire services and vehicle collision repair scenarios.

Optimizing Spot Welding for Enhanced Strength

Optimizing spot welding equipment is a precise art that enhances the structural integrity of high-strength steels used in modern automobiles. By controlling factors such as current, pulse duration, and cooling time, welders can achieve exceptional strength and durability. Advanced spot welding machines now incorporate sophisticated algorithms and sensors to precisely tailor these parameters, ensuring consistent quality. This meticulous process is crucial for auto repair services and collision repair services, where structural integrity is paramount to ensure safety and minimize the need for costly dent removal procedures.

The use of high-strength steels in vehicle manufacturing necessitates a correspondingly advanced spot welding technique. Traditional methods may not yield optimal results with these materials, leading to weaknesses or inconsistencies in welds. Modern spot welding equipment overcomes these challenges by employing targeted heat input and precise control, resulting in strong, reliable bonds that meet the demanding standards of today’s automotive industry. This innovation not only streamlines assembly lines but also enhances the overall safety and reliability of vehicles on the road.

Spot welding equipment plays a pivotal role in shaping modern manufacturing processes, especially with the advent of high-strength steels. By understanding the fundamentals of spot welding and its interaction with these advanced materials, manufacturers can optimize their processes to achieve superior structural integrity. High-strength steels, renowned for their robust properties, present unique challenges that require precise control over welding parameters. Through careful optimization, spot welding equipment can deliver consistent, high-quality welds, ensuring the strength and durability of components in demanding applications. This advanced technique not only streamlines production but also enhances the overall performance of products relying on these powerful alloys.