Spot welding equipment is essential for auto body repair, offering precise, efficient bonds using electrical current. Key components include power supplies, electrodes, and control mechanisms for consistent quality across varying materials. Its precision and speed make it ideal for complex dent repairs, restoring vehicles to pre-accident condition while preserving aesthetics and value. Choosing the right equipment with compact designs, effective heat control, and ease of use ensures safe, efficient repairs from simple dent removal to comprehensive vehicle services.

Spot welding equipment is an essential tool for seamless auto repair, offering precision and efficiency in metal joining. This article guides you through the basics of spot welding, highlighting its ideal applications in automotive repairs. We’ll explore how to choose the right tools, ensuring both optimal performance and safety. Learn when to employ spot welding equipment for clean, durable welds that meet modern automotive standards.

- Understanding Spot Welding Equipment Basics

- Ideal Applications for Seamless Auto Repairs

- Choosing the Right Tools for Efficiency and Safety

Understanding Spot Welding Equipment Basics

Spot welding equipment is a specialized toolset essential for any automotive body shop engaging in precise and efficient vehicle repair. This technique involves using high-current electrical energy to fuse two metal sheets together, creating a strong, permanent bond. The process is quick, clean, and highly effective for joining components in both new car manufacturing and collision damage repair.

Understanding the basics of spot welding equipment involves grasping its key components: power supply, electrodes, and control mechanisms. Power supplies generate the high-amplitude electrical current needed to melt and fuse metal. Electrodes, typically made of copper or tungsten, conduct this current directly to the workpiece, while control mechanisms allow for precise adjustment of current flow and duration, enabling welders to achieve consistent, quality bonds across various material thicknesses and types, common in automotive body shop applications.

Ideal Applications for Seamless Auto Repairs

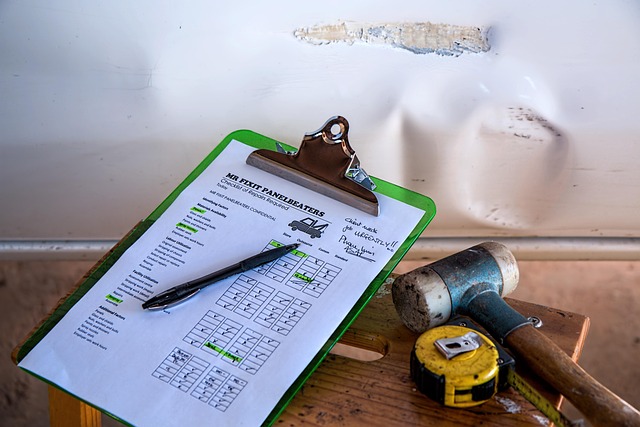

Spot welding equipment is an invaluable asset for any auto repair shop looking to offer seamless car body restoration services. Its ideal applications include complex vehicle dent repairs where precision and speed are paramount. This method allows for quick, strong, and clean welds on tight spots that traditional methods might struggle with, making it a game-changer in the world of auto repair.

From minor fender benders to significant collision damage, spot welding can be instrumental in returning vehicles to their pre-accident condition. Its ability to create nearly invisible welds ensures that cars not only look like new but also perform as expected on the road. This is particularly beneficial for customers seeking high-quality, discreet repairs that preserve the vehicle’s original aesthetic and value.

Choosing the Right Tools for Efficiency and Safety

Selecting the appropriate spot welding equipment is paramount for efficient and safe vehicle repair, especially when dealing with intricate metalwork. The right tools can significantly streamline the dent removal process, making it easier to achieve precise results, particularly in tight spaces. For instance, advanced spot welders often come equipped with compact designs, allowing them to access hard-to-reach areas within a vehicle’s body—a feature invaluable for detailed tire services and complex vehicle repair tasks.

When choosing your spot welding equipment, consider factors like power source (electrical or battery), heat control settings, and ease of use. These considerations ensure that the process is not only effective but also reduces the risk of accidents or inconsistencies during repairs, whether you’re tackling a simple dent removal job or more comprehensive vehicle repair services.

Spot welding equipment is a versatile and efficient tool for seamless auto repairs, offering precision and speed in various applications. By understanding the basics of this technique and selecting the right tools, professionals can enhance their workflow and produce high-quality results. Whether it’s for body panels, frames, or other metal components, spot welding provides a strong and reliable bond, making it an indispensable skill in the automotive repair industry.